O

ver the years Hastings had been asked many times to consider merging his company into a larger one. Sometimes the proposals had come in as form letters; other times they were individually-written letters from excellent companies. In all cases he had turned them down, and looking back he was pleased with his decision.

Since the mid-1950's the company's earnings had increased rapidly, and the company had enjoyed a healthy expansion financed by its own money. Going it alone had been extremely profitable.

But Hastings knew there were problems on the horizon that might make merger a good idea. He had been disappointed with the company's rate of growth for the last few years. In the future, he believed, it would be more and more difficult to pursue some of his present policies without strangling the company's opportunity for growth.

There were limits on the amount of government business a company could do without keeping more detailed cost records and without allowing government auditors and inspectors into the plant. He was big enough already that these limits were beginning to cause problems. The right merger might solve that problem. Perhaps another division of the parent company could manufacture equipment that called for military specifications, in-plant inspections, or government audits of cost data.

In addition he thought the future development of HRI products would benefit if the company worked closely with companies in allied fields. If the companies were part of the same organization, it would make this easier.

Merging with a good company listed on a major stock exchange would give Hastings-Raydist stockholders the security of a more diversified company. It would also improve the marketability of their shares.

The present company officers were approaching retirement age. Deaths or retirements of officers of small companies often knocked down the stock price considerably, as the market assessed the ability of the new officers to carry on. A merger would spare the stockholders this risk.

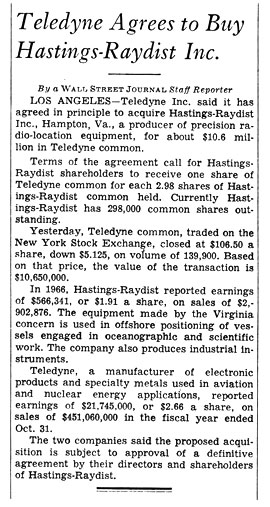

News of the proposed acquisition appears in The Wall Street Journal on January 31, 1968.

|

He had kept his eye on what happened to small companies that merged into larger ones. He knew it was standard for an acquiring company to claim that it allowed its acquisitions to continue on as before, but the record showed that some did and some didn't.

After a careful consideration of several possibilities, he decided that he wanted to have Hastings-Raydist acquired by Teledyne, Inc. He knew a lot about Teledyne. He had met several of its officers when Teledyne had bought Automated Specialties. He knew several Teledyne companies with which he thought Hastings-Raydist might work to mutual benefit. He had talked with officers of some of the companies Teledyne had acquired, and he liked what they had told him about what it was like to be part of Teledyne.

Hastings' interest in Teledyne was matched by Teledyne's interest in his company. Attracted to HRI's product line, its financial position, and its management, Teledyne was eager to acquire Hastings-Raydist.

On January 30, 1968, the two companies announced that they had reached an agreement in principle for Teledyne to acquire Hastings-Raydist. One share of Teledyne would be exchanged for each 2.98 shares of HRI, placing the value of Hastings-Raydist at approximately $10,600,000.

On March 27 the stockholders of Hastings-Raydist met to vote on the proposed agreement. Of the 298,899 shares of stock outstanding, 95.7 per cent were represented at the meeting, and 93.5 per cent were voted in favor of the acquisition. Only 2.2 per cent were opposed.

Even with such a high vote in favor of joining Teledyne, there were still mixed feelings. Louis Peterson, a stockholder for many years, expressed the feelings of many when he raised his hand during the meeting and said to Hastings, "I think that one of the reasons that there is such a large turnout here tonight is because all of us here have a tremendous amount of sentimental attachment to you and the business. It's a home-town-boy-makes-good story, and we are proud to have been part of it. As my wife and I were driving here tonight I said to her, 'We go out so seldom, we go only to weddings and wakes—I'm not sure which we're going to tonight.'"

Only time would tell.

O

ver the years the company's glamorous jobs usually had fallen to Raydist, but in 1967 Hastings-Raydist began work on a project that put the company's vacuum equipment in the limelight. A Hastings thermopile was scheduled to go on the Apollo 11 flight to the moon. The launch was set for July 16, 1969.

Mary Whitley uses a microscope to weld Hastings thermocouples into a moon rock box.

Close-up showing thermocouples in box.

Thermocouples destined for the moon.

|

On the moon, astronauts will put samples of the lunar surface into special boxes to be returned to Earth.

Back on Earth, the moon rock box arrives at the Manned Spacecraft Center in Houston.

|

The Apollo flight would carry two specially-built boxes for bringing samples of moon rocks back to Earth. Each box would be evacuated and sterilized before the launch. On the moon the astronauts would open the boxes, fill them with samples of the moon's surface, and reseal them. When the boxes returned to Earth, they would be opened and their contents examined in a sterile environment.

A critical feature was that each box have a vacuum-tight seal. To be sure the seal was working properly, scientists would check the pressure inside each box just before the launch. If the box was at a vacuum, they would know it was not contaminated before it left Earth. After the boxes returned from the moon, scientists would check the pressure in each box just before opening it. A vacuum inside would assure them that the astronauts had made a good seal when they closed the box, and that the contents of the box had not been contaminated by air or bacteria since the return to Earth.

Oak Ridge National Laboratories of Tennessee, in charge of designing and building the boxes, chose Hastings-Raydist to provide the equipment for measuring the vacuums.

A Hastings thermopile weighing only a millionth of a pound was installed inside each box in a recess near the handle. A plug with electrical contacts to the thermopile came through the seal so that the pressure could be measured from the outside.

Charlie Hawk was the Hastings project engineer for the job. He recalls:

The difficult part of this project wasn't finding a thermopile that would survive the trip to the moon, but finding one that would survive the trip through the "washing machines" at Oak Ridge. As part of the pre-launch sterilization process, each box had to be treated with cleaning solutions and then given an ultrasonic cleaning at different powers and frequencies. At first we were using thermopiles with long, thin, wires, and their ultrasonic cleaner was using 1200 watts. The vibration at that power broke off the thermopiles. After some experimentation, we ended up using wires that were a little shorter and about three times the diameter of our first wires, and they lowered the power on the ultrasonic cleaner to 400 watts. After that the thermopiles came through the cleaning unscathed, and we had no further trouble. The same boxes were used again on later Apollo flights, however, so to be on the safe side we replaced the thermopiles after each flight.

One of the thermopiles that went to the moon and back on the Apollo 14 flight is now on display in the company's lobby.

B

ack in the fall of 1954 a representative from Exxon's Bayway refinery had approached Charlie Hawk at a trade show. He was looking for something to measure the amount of waste gas going up a flare stack, so that he could monitor the efficiency of his refining processes. He wondered if the Hastings thermopile techniques might do it.

As a result, HICO introduced its first "gas flow probe" in 1955. Basically an Air-Meter, it had small, fine thermocouple wires in the flow stream and measured the rate of cooling.

The device was not without problems. The inside of a flare stack is so dirty that grime quickly covered the thermocouples, leaving them insensitive to the flow. In addition, the thermocouples were destroyed by each blowout, and the instrument changed calibration as gas composition varied. After a few years the probe was discontinued.

In the early 1970's Jim Benson and Charlie Hawk had another idea for a gas flow probe. What if they used the patented thermal principle behind the company's mass flowmeter? One good feature of such a probe would be that it would have no elements in the flow stream. The flow would go through capillary tubing that had the sensors on the outside. If the tubing became plugged up, solvents or an airgun could clean it without doing any damage.

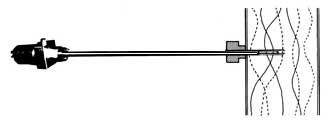

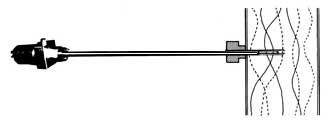

Diagram of gas flow probe with tip in flow stream.

|

When they tried the idea, they found that dirt and condensation clogged the narrow tubing so rapidly that it was impossible to keep it open for a reasonable length of time. Then Benson suggested that they continuously purge the system with a source of air. The result would be a probe that looked like a pitot tube in a flow stream but would have air constantly flowing out of it.

They built a probe with two openings at the probe tip, and connected the openings internally with stainless steel tube. To purge the system, they injected air into it in such a way as to create a pneumatic version of the Wheatstone bridge. When there were no gases going up the flare stack, the bridge was balanced so that no flow occurred through the sensing section of the tube, and the purge gas exhausted equally from both openings at the probe tip.

Then a gas flow in the flare stack across the probe tip created a differential pressure, unbalanced the bridge, and caused a very small amount of purge gas to flow through the sensing section. External thermo-electric sensors measured the flow in the flare stack by measuring the amount of purge gas flowing through the sensing section. Meanwhile purge gas still flowed out both openings into the flare stack, preventing the stack's gases from entering the probe and clogging it up.

Hastings-Raydist had finally found a way for refineries and power plants to measure the waste gases from their flare stacks and furnaces. "We think of it," says Hawk, "as a cross between an Air-Meter and a flowmeter. Being a probe device, it measures velocity and works like an Air-Meter, but on the other hand it uses the mass flowmeter as a sensor. The instrument was badly needed—it does a job that practically nothing else will. Not only that, it's reasonably priced for what it does."

S

everal new versions of Raydist made their appearance in the late sixties and early seventies. In 1967 DRS Raydist was introduced. Available as either a range system or a hyperbolic system, DRS reduced the number of required frequencies from three to two.

Then came the Raydist "T" System, a hyperbolic system with four base stations instead of the usual three. The fourth station vastly improved the geometry of grid patterns, increasing the area of good coverage and the level of accuracy.

The U.S. Navy has developed Omega, a navigational system allowing vessels and aircraft with Omega receivers to determine their position within approximately one mile in the daytime and two miles at night anywhere on earth. Such accuracy is acceptable on the high seas, but for many applications, such as in crowded harbors and shipping lanes, greater accuracy is needed. To supplement this system Hastings-Raydist developed Micro-Omega. Used in conjunction with Omega, Micro-Omega makes a 10:1 improvement in Omega's accuracy.

T

hirty-one miles off Cape Henry, Virginia, is Triangle Reef, an artificial fishing reef covering a six-mile square area. The marine plants and barnacles that grow on artificial reefs attract thousands of small fish. These fish, in turn attract the larger game fish that feed on the smaller fish. Prior to August 1974, Triangle Reef had in it at least three and perhaps four large ships that were sunk by German U-boats during World War II. It also had the deliberate addition of more than 100 surplus landing craft and thousands of tires and concrete blocks.

In 1974 the Liberty ship Webster is sunk as part of a project to create an artificial fishing reef off the coast of Virginia. Above: the Webster is dynamited. Below: the ship sinks.

|

In August 1974, the Liberty ship Webster, with the help of Raydist, was added to the reef.

Before the sinking, National Ocean Survey vessels performed a detailed hydrographic survey of the reef. A successful sinking of the Webster required that the ship land within the reef area and that no part of the vessel be less than 70 feet below the surface after settling into place. The preliminary surveys, made by NOS vessels and the Hast-Ray II, showed a depression in the ocean floor just barely deep enough to meet the 70 foot requirement. Since any error in position would be irrevocable after the sinking and the vessel could become a navigational hazard, accuracy was essential. A Raydist "T" system, extremely accurate in the area offshore from the Virginia Capes, was chosen for the job of positioning the Webster.

Once the Webster was in position, the ship was dynamited. It sank in 7 minutes, 23 seconds.

Immediately after the sinking, the Hast-Ray II passed over the sunken hull to determine the results. The ship had settled to the bottom, and the top of the vessel was 71 feet below the surface of the water. Raydist had completed another successful project.

I

n 1970 Hastings-Raydist began setting up a Raydist "T" system to cover the Chesapeake Bay, and by 1973 the entire bay was covered. Any boat with a Raydist receiver could now determine its position in the bay within ten feet, and return to within three feet of a selected spot.

The Virginia Institute of Marine Science brings one of its vessels to the Hastings-Raydist dock for installation of Raydist equipment.

|

The system has been helpful to many groups that use the bay. Both the Maryland Department of Natural Resources and the Virginia Institute of Marine Science use it to sample shellfish populations and to place and retrieve scientific instruments. The Virginia Marine Resources Commission uses it on police boats to enforce fishing regulations. In 1971 the Chesapeake Bay Institute of Johns Hopkins University used it on a project to make a seismic profile of the subbottom of the Chesapeake Bay. The U.S. Coast Guard has used it to position buoys, and the National Ocean Survey has used it both for hydrographic surveys and to detect and remove obstacles in navigable waters.

I

n 1971 the Army Medical Service purchased a Raydist "T" System to study how well pilots can fly helicopters under stress and fatigue. In wartime, pilots in far less than peak condition may find it necessary to fly. It is important to know how well they can be expected to perform under various circumstances. In the Fort Rucker experiments, a pilot suffering from loss of sleep, food deprivation, or some other impairing condition attempts to fly a series of intricate maneuvers. A normal pilot rides as copilot, ready to take over the controls if necessary. Raydist records the path actually flown, allowing an accurate evaluation of the pilot's ability to control the helicopter.

Above: Dexter Phibbs prepares for a training flight on a minesweeping helicopter. He will assist Navy pilot and crew with the Raydist equipment.

Below: Phibbs checks gear prior to flight. (1979)

|

I

n the summer of 1972, Charles Hastings read in the newspapers that the U.S. Navy had formed a helicopter mine countermeasures squadron. The Navy had never done airborne minesweeping before, and this new squadron was developing the techniques for it. As part of a minesweeping procedure, helicopters would fly over minefields dragging special sleds through the water. The sleds in turn would tow devices behind them that would trigger the mines. A crucial part of the procedure involved making sure the entire field was swept as efficiently as possible.

Here, thought Hastings, is where Raydist could fit in. Guiding helicopters over water in closely-spaced parallel lines would be very similar to the work Raydist routinely performed in geophysical and hydrographic work.

The new squadron was in Norfolk. Hastings contacted Captain Felix Vecchione, in charge of the squadron, and before long Hastings and several Raydist engineers were crossing Hampton Roads in the Hast-Ray to take a group of naval officers out for a Raydist demonstration.

The demonstration went well. "I've got to have this," commented Vecchione after seeing Raydist work.

The Navy leased a Raydist system and sent it to its minesweeping practice area near Charleston, South Carolina, for testing. It performed beautifully.

By now minesweeping was becoming a pressing political issue. Negotiations between the United States and North Vietnam for the release of U.S. prisoners of war were being tied to U.S. willingness to clear the mines from North Vietnamese waters. On November 3, the Navy ordered 33 Raydist systems for its helicopters, plus a Raydist ground network of antennas and transmitters. It wanted everything ready by January.

The shops at Hastings-Raydist immediately began working sixty hours a week. Research personnel were pressed into manufacturing, and engineers were put into inspection. In addition, production was subcontracted to Teledyne Avionics (the former Automated Specialties) in Charlottesville, Virginia, and to Teledyne Systems in Lewisburg, Tennessee.

Every morning there was a Raydist troubleshooting meeting to identify the day's most pressing problems. Then everyone went off in different directions to break bottlenecks, expedite procurement, or do whatever else was called for.

One of the biggest problems was getting the necessary parts on such short notice. Whenever a procurement problem arose, whoever had the best entree with that supplier would call up the president of the company or anyone else he knew who could expedite delivery. Before the job was over, all Hastings-Raydist officers were experienced expediters.

By the time the cease-fire was signed in January 1973, the Raydist equipment was ready and waiting. It was sent to Subic Bay in the Philippines, where the Navy practiced its techniques for a few weeks before beginning the job in North Vietnam.

Two Raydist technical representatives were sent out on the job. They set up Raydist base stations on the beaches of North Vietnam, and assisted with the equipment in the helicopters. Part way through the job, the prisoner of war negotiations broke down. The U.S. immediately discontinued the minesweeping, and as a result the negotiations were back on track in less than a week.

Directed by Raydist, four Navy minesweeping helicopters fly in formation.

|

When it was all over, Captain Vecchione came to the company to thank its personnel and to give a slide presentation on the Vietnam minesweeping operations.

"I feel very strongly," he said, "that much of the success of our operation out there was due to the great job this company's people did in responding to our cry for precise navigation systems. … Without this equipment, I am sure that we would have been, if not unsuccessful, at least less successful than we were."

A year later, in early 1974, the United States agreed to help Egypt reopen the Suez Canal. The canal had been closed since 1967, when it became blocked with wrecks and laced with mines during the October War between Egypt and Israel.

The United States and Great Britain were to clear the mines and wrecks from the canal, while the Russians were to sweep the mines from the approaches to the canal. The same U.S. Navy squadron that had cleared the mines from North Vietnamese harbors was sent to the Suez, and Raydist guided the helicopters as they cleared the minefields.

The Russians failed to clear an approach to the canal near Port Said, and in 1975 an American ship sank after striking a Soviet mine there. U.S. minesweeping helicopters were dispatched to the area, and again Raydist assisted them in their job.

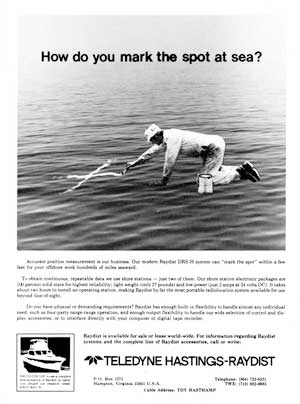

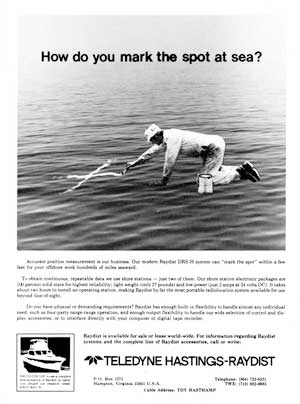

"How do you mark the spot at sea? " becomes a theme of Raydist advertising.

|

C

harles Hastings was delighted with the way the merger with Teledyne was working out. The company was prospering, and he, relieved of some of the responsibilities and paperwork of being president of an independent company, was having more time available to devote to engineering.

He had found several opportunities to work with other Teledyne companies. In addition to Teledyne Avionics and Teledyne Systems, which had helped to make the Raydist equipment for the Vietnam minesweeping, Teledyne Geotech was making Raydist accessory equipment.

Joining Teledyne had brought relatively few changes to the operations of his company. One of the few changes was in the profit-sharing plan. Since Teledyne did not disclose the annual profits of individual member companies, the profit-sharing plan was discontinued. To compensate for this, all employees received a major pay raise. The money already in the profit-sharing fund, over $2,000,000, was distributed to the employees.

True to its word, Teledyne was not interfering with his decisions about how to run his company. Unlike most Teledyne companies, which are organized into groups and report to a "group executive," his company reported directly to Teledyne headquarters. There he dealt with Teledyne's president George Roberts and chairman of the board Henry Singleton, both of whom he admired and respected enormously.

The merger had indeed turned out to be a wedding rather than a wake.

next chapter >>

Copyright © by Carol Hastings Sanders

|